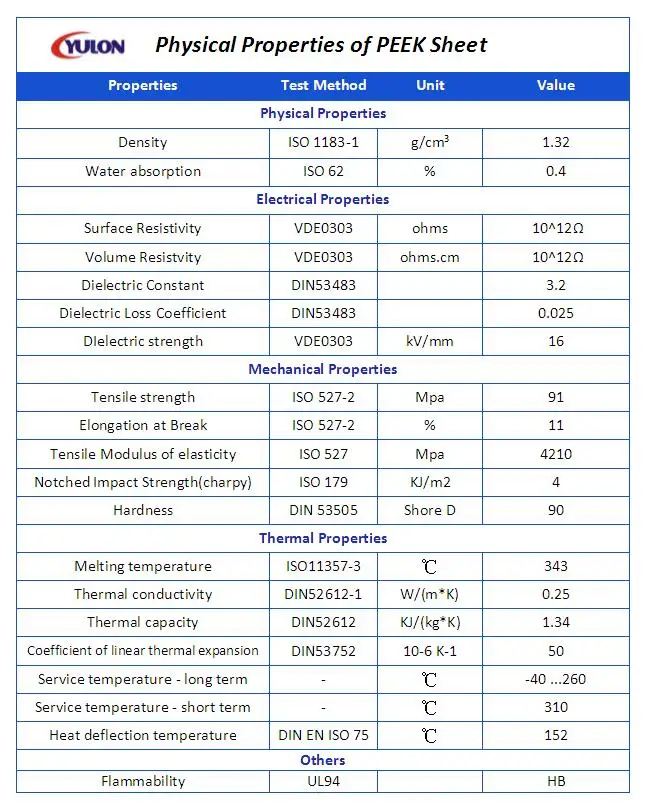

We manufacture PEEK semi-finished products including rod, tube and sheet by compression moulding. It is extensively used in the aerospace, automotive, and chemical process industries. It is one of the few plastics compatible with ultra-high vacuum applications. It dissolves completely in concentrated sulfuric acid at room temperature.īecause of its robustness, PEEK is used to fabricate items used in demanding applications, including bearings, piston parts, pumps, HPLC columns, compressor plate valves, and cable insulation. It is attacked by halogens and strong acids as well as some halogenated compounds and aliphatic hydrocarbons at high temperatures. It is highly resistant to thermal degradation as well as attack by both organic and aqueous environments. Some grades have a useful operating temperature of up to 250 ☌ (482 ☏). PEEK has a glass transition temperature of around 143 ☌ (289 ☏) and melts around 343 ☌ (662 ☏). The Young's modulus is 3.6 GPa and its tensile strength 90 to 100 MPa. The processing conditions used to mold PEEK can influence the crystallinity, and hence the mechanical properties. PEEK is a semicrystalline thermoplastic with excellent mechanical and chemical resistance properties that are retained to high temperatures. Polyether ether ketone (PEEK) is a colourless organic thermoplastic polymer in the polyaryletherketone (PAEK) family, used in engineering applications. Our range includes over 500 materials that offerĮxceptional characteristics enabling them to operate in Our company Fluorinoid® register, based on elastomer, PTFE and thermoplastic technologies includes over 500 materials that offer exceptional characteristics enabling them to operate in demanding environmental conditions at temperatures to over 300☌. In Fluoropolymer materials, coatings and Advanced An extensive range of standard and bespoke solutions

0 kommentar(er)

0 kommentar(er)